Main Products

CONTACT US

Address: No.5 Shunhai Road, Yangting Town, Weihai City, Shandong Province

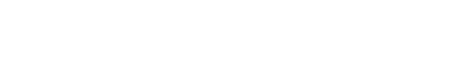

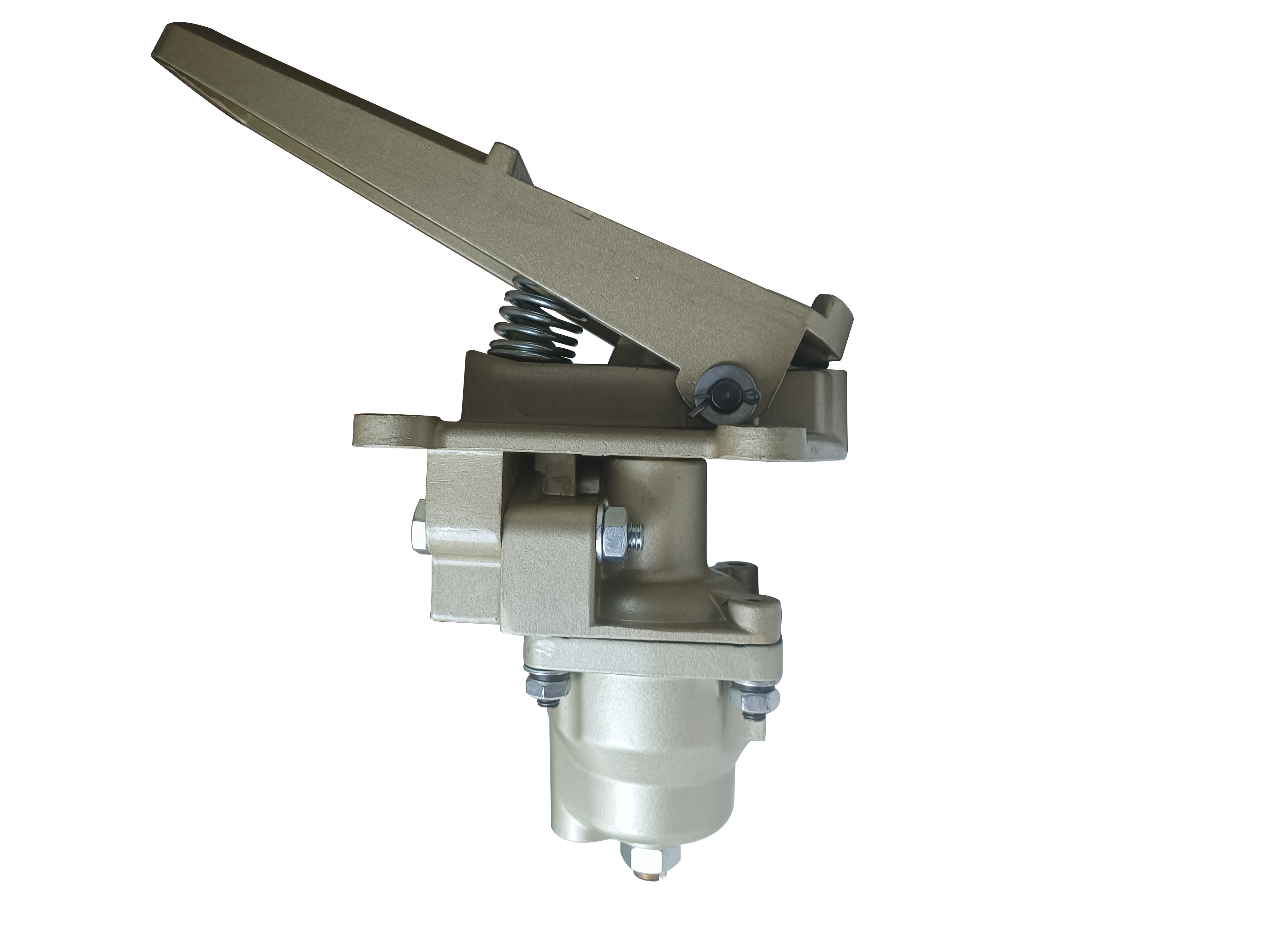

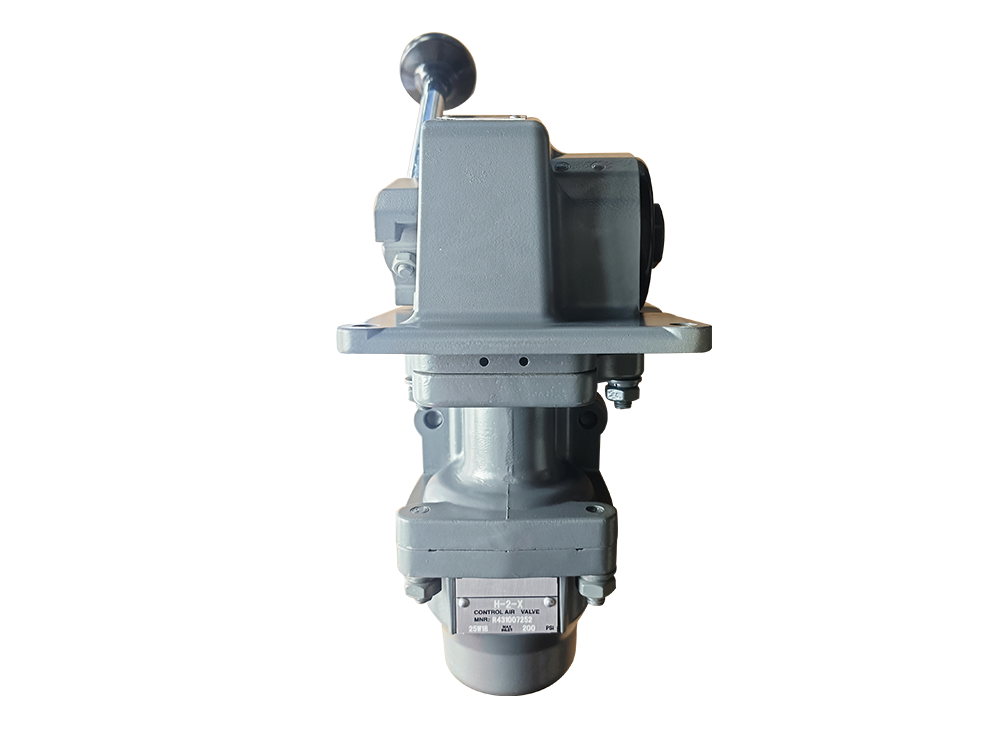

Series FCA Air Pressure Regulators

零售价

市场价

Keywords:

Series FCA

Category:

Tel:

E-mail:

重量

库存

隐藏域元素占位

- Detail

- Dimension in Inches

-

- Commodity name: Series FCA Air Pressure Regulators

- Commodity ID: 022

The FCA Valve is a highly versatile pressure control valve with many assembly combinations for a wide variety of control functions. There are three valve cavities in the body which may contain several types of valve assemblies or may be plugged. Two standard handle lengths, plus an adjustable handle, are available. Various handle guide inserts limit the handle motion to the desired areas of travel. The handle return characteristic may be one of three different types.

1. Description

As the handle is moved forward, a definite and precise outlet pressure is delivered. If downstream pressure drops, the FCA will compensate to maintain outlet pressure (without further handle movement). The handle may be moved forward, backward, to one side, or in combination of directions to control pressure in one or two of the three outlet ports. Handle movement forward or backward provides air pressure proportional to handle movements; handle movement to one side operates an on-off valve. Handle guides can be included in the valve to limit handle movement to certain areas or to control sequencing.

Although most valves operate as described above, any of the three directions can deliver a pressure proportional to handle travel (pressure control valve), control an on/off (3-way) valve, or have no valve at all. Forward movement controls valve #1, backward movement controls valve #2, and sideward movement controls valve #3. When used for pressure graduation, valves #1 and #2 deliver and maintain a more precise outlet pressure than the valve in cavity #3.

The handle is available in two lengths. Either handle length can be spring returned or detented. Short handles can include an adjustable friction option.

2. Operation:

Pressure Graduating Valves: The precise pressure control of the FLEXAIR Valve, and its ability to change outlet pressure in small increments is obtained through the use of a spring balanced piston. With the handle in the center position, the inlet valve is held closed by the inlet spring. The outlet port is connected to atmosphere through the hollow plunger in the inlet valve. When the handle is moved, the exhaust valve moves down to seal off the exhaust port. Further movement unseats the inlet valve to connect the inlet port to the outlet port and the underside of the piston. Air pressure builds up in the outlet line and underneath the piston. When the air pressure (working on the piston’s area) overcomes a spring on top of the piston, the inlet valve seats.

Further movement of the handle to increase pressure depresses the valve assembly, and again opens the supply valve. Pressure is increased in the outlet line and below the piston until another balanced condition occurs at the higher pressure.

Movement of the handle to decrease pressure decreases the force on the valve assembly, and allows the air pressure and return spring to raise the piston and unseat the exhaust valve. Pressure is therefore vented from the outlet line until it is reduced to the value called for by the handle position.

Should leakage or a temperature variation occur that would change the outlet line pressure called for by the handle position, this deviation in pressure opens either the inlet valve or exhaust valve to restore the correct pressure.

3-Way Valves: With the handle in the center position, the inlet valve is held closed by the inlet spring. The outlet port is connected to atmosphere through the hollow plunger. When the handle is moved, the exhaust valve moves down to seal off the exhaust port and unseat the inlet valve. The inlet pressure then pressurizes the outlet port to full pressure.

Movement of the handle back to center position allows the inlet spring to close off the inlet port and open the delivery port to exhaust.

3. Handle Types:

Three types of handle return or holding functions are available:

1. Detent - The handle, when released, returns to its center position from all positions except extreme travel (fully applied) for valve cavities #1 and #2. A detent holds the handle in the two fully applied positions for valve cavities #1 and #2. This detent force is adjustable.

2. Friction - The handle will remain in any applied position for valve cavities #1 and #2 when released. This friction is adjustable. (For short handle only)

3. Spring Returned - Handle returns to its center position from all positions when released.

4. Technical Data:

Port sizes 1/4"-18 NPTF Temperature range -40°C to +70°C Media Air, clean and dry Weight 2.7 kg 5. Pressure Data:

GRADUATING VALVES

CAVITIES #1 & #2

(Operation toward or away from operator)

Side Graduating Valve: Cavity #3

With full pressure setting:

0-40 or 0-70 psi (0-2.8 or 0-4.8 bar)

Without full pressure setting:

0-65 or 0-100 psi (0-4.5 or 6.9 bar)

-

1. FRICTION TYPE

2. SPRING RETURNED & DETENT TYPE

Series FCA Air Pressure Regulators

The FCA Valve is a highly versatile pressure control valve with many assembly combinations for a wide variety of control functions. There are three valve cavities in the body which may contain several types of valve assemblies or may be plugged. Two standard handle lengths, plus an adjustable handle, are available. Various handle guide inserts limit the handle motion to the desired areas of travel. The handle return characteristic may be one of three different types.

keyword:

Category:

Series FCA Air Pressure Regulator

Tel:

E-mail:

- Detail

- Dimension in Inches

-

- Commodity name: Series FCA Air Pressure Regulators

- Commodity ID: 022

The FCA Valve is a highly versatile pressure control valve with many assembly combinations for a wide variety of control functions. There are three valve cavities in the body which may contain several types of valve assemblies or may be plugged. Two standard handle lengths, plus an adjustable handle, are available. Various handle guide inserts limit the handle motion to the desired areas of travel. The handle return characteristic may be one of three different types.

1. Description

As the handle is moved forward, a definite and precise outlet pressure is delivered. If downstream pressure drops, the FCA will compensate to maintain outlet pressure (without further handle movement). The handle may be moved forward, backward, to one side, or in combination of directions to control pressure in one or two of the three outlet ports. Handle movement forward or backward provides air pressure proportional to handle movements; handle movement to one side operates an on-off valve. Handle guides can be included in the valve to limit handle movement to certain areas or to control sequencing.

Although most valves operate as described above, any of the three directions can deliver a pressure proportional to handle travel (pressure control valve), control an on/off (3-way) valve, or have no valve at all. Forward movement controls valve #1, backward movement controls valve #2, and sideward movement controls valve #3. When used for pressure graduation, valves #1 and #2 deliver and maintain a more precise outlet pressure than the valve in cavity #3.

The handle is available in two lengths. Either handle length can be spring returned or detented. Short handles can include an adjustable friction option.

2. Operation:

Pressure Graduating Valves: The precise pressure control of the FLEXAIR Valve, and its ability to change outlet pressure in small increments is obtained through the use of a spring balanced piston. With the handle in the center position, the inlet valve is held closed by the inlet spring. The outlet port is connected to atmosphere through the hollow plunger in the inlet valve. When the handle is moved, the exhaust valve moves down to seal off the exhaust port. Further movement unseats the inlet valve to connect the inlet port to the outlet port and the underside of the piston. Air pressure builds up in the outlet line and underneath the piston. When the air pressure (working on the piston’s area) overcomes a spring on top of the piston, the inlet valve seats.

Further movement of the handle to increase pressure depresses the valve assembly, and again opens the supply valve. Pressure is increased in the outlet line and below the piston until another balanced condition occurs at the higher pressure.

Movement of the handle to decrease pressure decreases the force on the valve assembly, and allows the air pressure and return spring to raise the piston and unseat the exhaust valve. Pressure is therefore vented from the outlet line until it is reduced to the value called for by the handle position.

Should leakage or a temperature variation occur that would change the outlet line pressure called for by the handle position, this deviation in pressure opens either the inlet valve or exhaust valve to restore the correct pressure.

3-Way Valves: With the handle in the center position, the inlet valve is held closed by the inlet spring. The outlet port is connected to atmosphere through the hollow plunger. When the handle is moved, the exhaust valve moves down to seal off the exhaust port and unseat the inlet valve. The inlet pressure then pressurizes the outlet port to full pressure.

Movement of the handle back to center position allows the inlet spring to close off the inlet port and open the delivery port to exhaust.

3. Handle Types:

Three types of handle return or holding functions are available:

1. Detent - The handle, when released, returns to its center position from all positions except extreme travel (fully applied) for valve cavities #1 and #2. A detent holds the handle in the two fully applied positions for valve cavities #1 and #2. This detent force is adjustable.

2. Friction - The handle will remain in any applied position for valve cavities #1 and #2 when released. This friction is adjustable. (For short handle only)

3. Spring Returned - Handle returns to its center position from all positions when released.

4. Technical Data:

Port sizes 1/4"-18 NPTF Temperature range -40°C to +70°C Media Air, clean and dry Weight 2.7 kg 5. Pressure Data:

GRADUATING VALVES

CAVITIES #1 & #2

(Operation toward or away from operator)

Side Graduating Valve: Cavity #3

With full pressure setting:

0-40 or 0-70 psi (0-2.8 or 0-4.8 bar)

Without full pressure setting:

0-65 or 0-100 psi (0-4.5 or 6.9 bar)

-

1. FRICTION TYPE

2. SPRING RETURNED & DETENT TYPE

Product Message

Other Products