Main Products

CONTACT US

Address: No.5 Shunhai Road, Yangting Town, Weihai City, Shandong Province

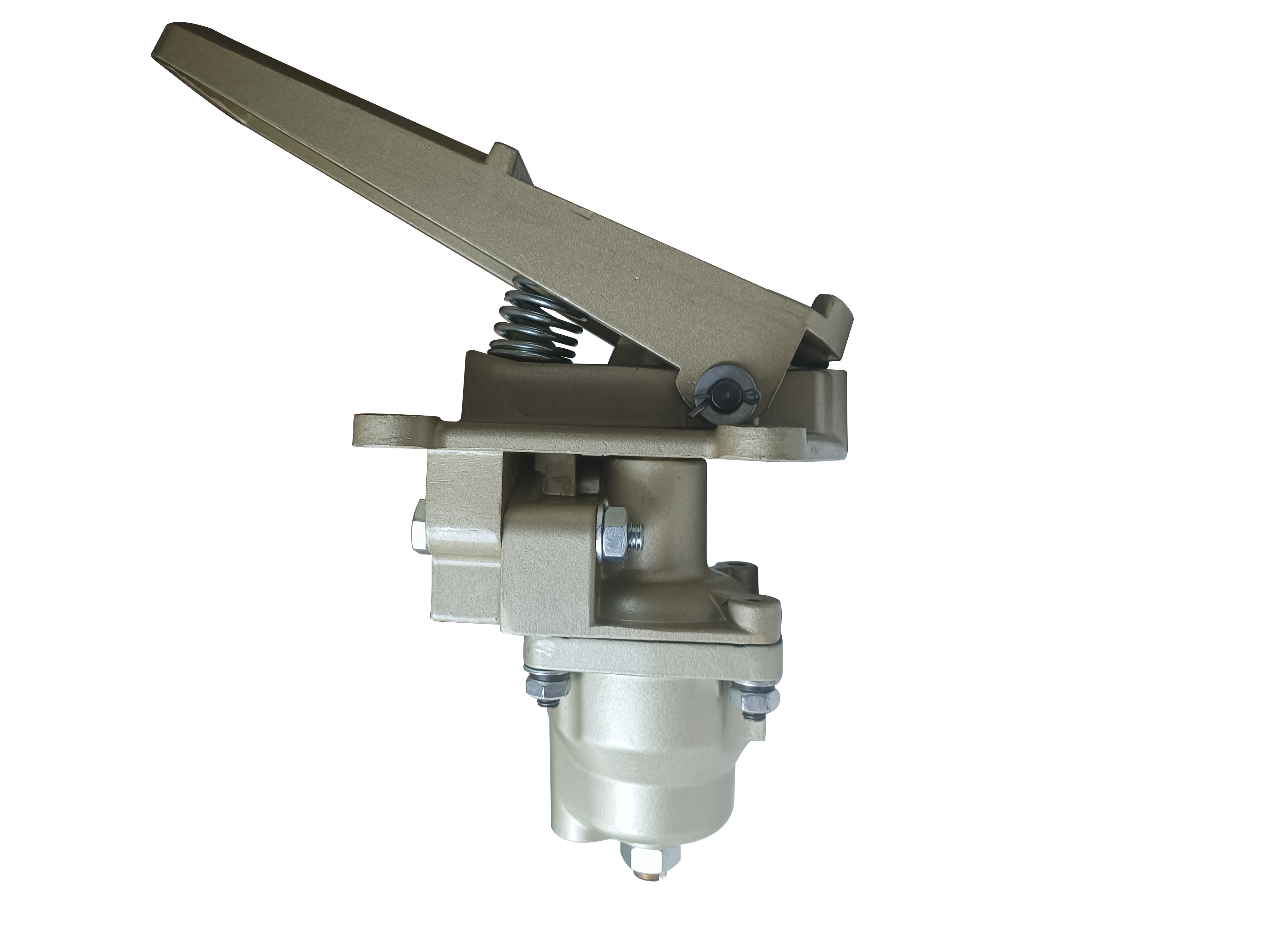

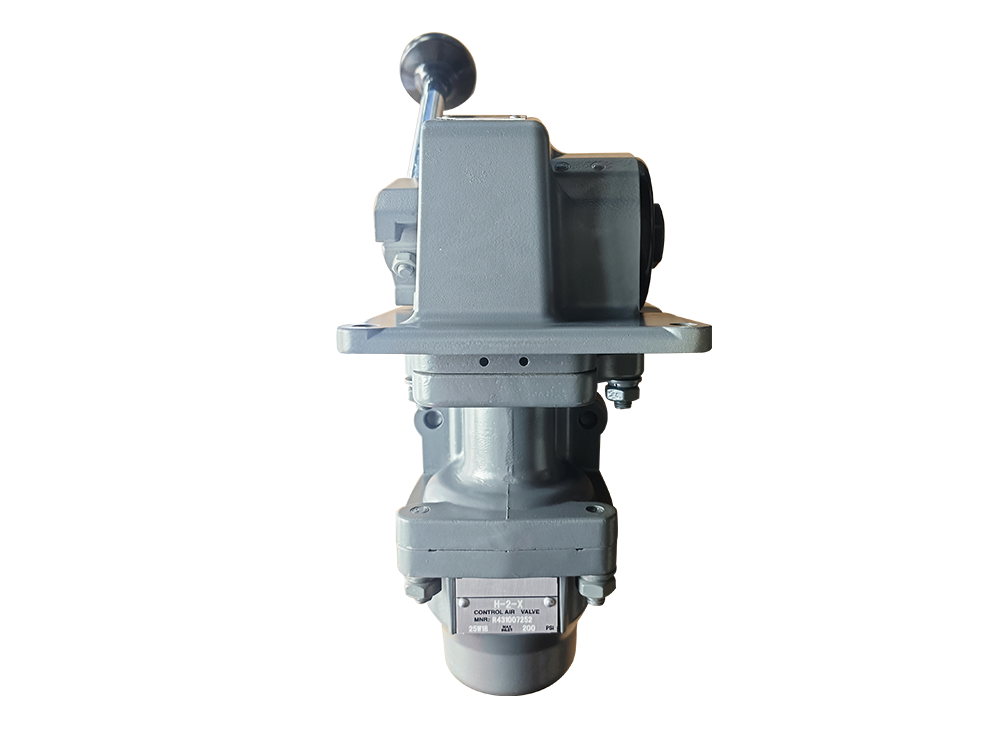

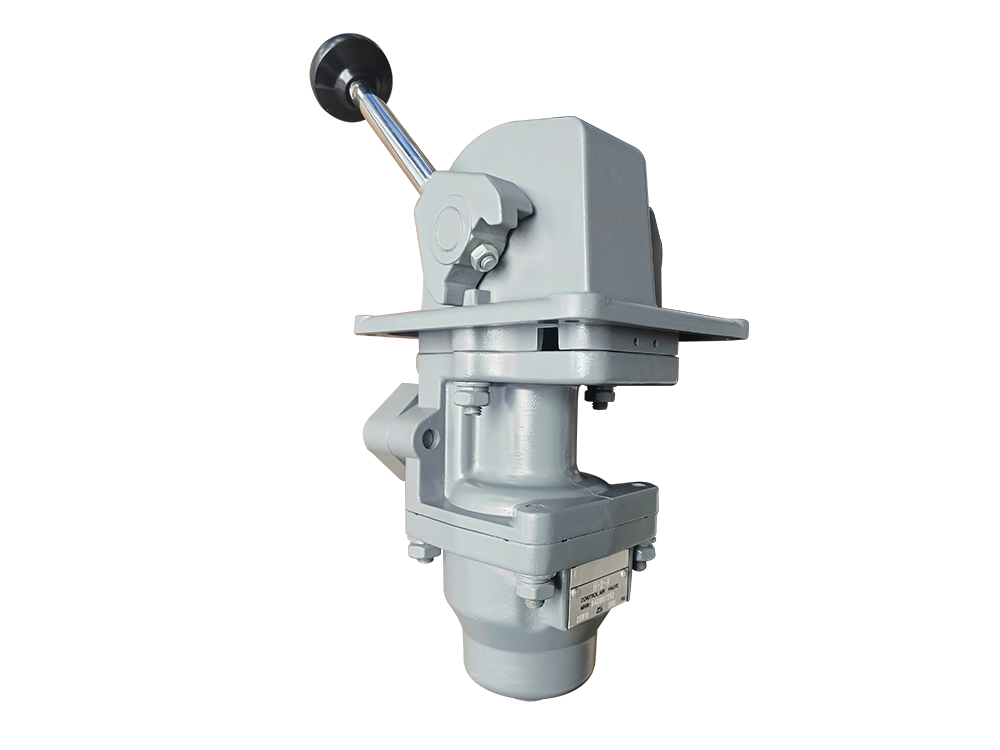

QGCX Series Mini Cylinder

零售价

市场价

Keywords:

QGCX Series

Category:

Tel:

E-mail:

重量

库存

隐藏域元素占位

- Detail

- Dimension in Inches

-

- Commodity name: QGCX Series Mini Cylinder

- Commodity ID: 239

The bore is made from stainless steel,and reduce friction and increas the cylinder life. The rod thread is extrusion and chromeplated and polishing,have good stainlss and seal rings structure and quality are very nice working without lubrication, start at low pressure,long service life.

1. Parameter

CylinderQGCXQGCX-KTypestandardwith switchBore(¢)121620253240Max. stroke(mm)200300400500600Mediumclean airPresusure(MPa)0.15--0.8Pressure-proof(MPa)1.2LubricationnotTemperature(ºC)5--60Speed mm/sec50--500Stroke tolerance(mm)0--250; 250--400 -

1. Standard (S type)

Bore(Ф) 12 16 20 25 32 40 A 16 16 20 22 22 24 S1 10 10 13 16 16 18 S2 22 22 30 30 32 40 CD(Ф) 6H9 6H9 8H9 8H9 10H9 12H9 E 20 23 26.5 30.5 38 46 EB 19 22 26 30 37 45 EW 12 12 16 16 16 20 H 33.2 35 35 38 40 43 H 3.2 3.2 6.8 9.3 9.3 12 K 9.9 10 15 15 15 15 KK M6 M6 M8 M10*1.25 M10*1.25 M12*1.25 Bore(Ф) 12 16 20 25 32 40 L 9 9 12 12 14 16 LL 53 55 65 68 70 73 MB M16*1.5 M16*1.5 M22*1.5 M22*1.5 M24*2 M30*2 MM(Ф) 6 6 8 10 12 14 P 43.2 45 50 53 55 58 RH 6 6 7 7 8 9 EE M5 M5 G1/8 G1/8 G1/8 G1/8 VF 16 17.5 16 18 20 22 WF 22 23.5 24 25 30 32 XC 84 87.5 100 105 114 121 ZC 91 94.5 110 115 126 133 2. With switch (K type)

4. Back axis(T)

5. Rod side flange(F1)

6. Head rod side flange(F2)

7. Front foot rest(G1)

8. Foot rest(G)

9. Front movable trunnion(B1)

10. Back movable trunnion(B2)

11. Support(Z)

11. Front movable trunnion & support(B1X)

12. Back movable trunnion & support(B2Z)

Bore(Ф) 12 16 20 25 32 40 AE 33 33 42 42 50 58 AH 20 20 25 25 32 36 AL 14 14 16 16 25 25 AT1 3 3.2 4 4 4 4 AT2 8 3.2 3.2 3.2 4 4 AV 11 11 13 13 21 21 BD 8 8 10 10 12 14 BF 24 24 32 32 36 40 BH 25 25 32 32 36 40 BG(Ф) 5.5 5.5 6.6 6.6 6.6 6.6 BT 3.2 3.2 3.2 3.2 4 4 BU 36 36 48 48 52 56 EF 26 26 38 38 47 51 KA 102 102 124 129 140 149 LB 14 14 16 16 25 25 ML 13 13 18 18 22 24 NL 12 12 17 17 20 21 PA 25 25 30 30 31 35 R 32 32 40 40 45 50 SA 81 83 97 100 120 123 SK 31 33 39 42 28 31 Bore(Ф) 12 16 20 25 32 40 TB 77 82.5 92 98 106 112 TD(Ф) 68 68 88 88 108 128 TF 40 40 50 50 58 70 TL 6 6 8 8 10 12 TM 28 28 36 36 44 50 TU 24 24 32 32 36 44 UA 44 44 55 55 60 65 UF 52 52 65 65 72 84 UM 40 40 52 52 64 74 WL 33 34.5 37 38 51 53 WM1 71 71 87 87 95 101 WM2 55 55 67 67 67 71 XG 18 19.5 19 20 24 23 XM1 59 59 71 71 79 85 XM2 43 43 51 51 51 55 XJ 73 75 91 95 102 108 XT 97 100 117 122 132 138 ZA 95 98.5 112 116 133 138 ZF 78 81.5 92 97 104 109 ZJ 75 78.5 88.5 93.5 101 106 ZX 69 71 85 90 96 101

QGCX Series Mini Cylinder

The bore is made from stainless steel,and reduce friction and increas the cylinder life. The rod thread is extrusion and chromeplated and polishing,have good stainlss and seal rings structure and quality are very nice working without lubrication, start at low pressure,long service life.

keyword:

Category:

Pneumatic Cylinder

Tel:

E-mail:

- Detail

- Dimension in Inches

-

- Commodity name: QGCX Series Mini Cylinder

- Commodity ID: 239

The bore is made from stainless steel,and reduce friction and increas the cylinder life. The rod thread is extrusion and chromeplated and polishing,have good stainlss and seal rings structure and quality are very nice working without lubrication, start at low pressure,long service life.

1. Parameter

CylinderQGCXQGCX-KTypestandardwith switchBore(¢)121620253240Max. stroke(mm)200300400500600Mediumclean airPresusure(MPa)0.15--0.8Pressure-proof(MPa)1.2LubricationnotTemperature(ºC)5--60Speed mm/sec50--500Stroke tolerance(mm)0--250; 250--400 -

1. Standard (S type)

Bore(Ф) 12 16 20 25 32 40 A 16 16 20 22 22 24 S1 10 10 13 16 16 18 S2 22 22 30 30 32 40 CD(Ф) 6H9 6H9 8H9 8H9 10H9 12H9 E 20 23 26.5 30.5 38 46 EB 19 22 26 30 37 45 EW 12 12 16 16 16 20 H 33.2 35 35 38 40 43 H 3.2 3.2 6.8 9.3 9.3 12 K 9.9 10 15 15 15 15 KK M6 M6 M8 M10*1.25 M10*1.25 M12*1.25 Bore(Ф) 12 16 20 25 32 40 L 9 9 12 12 14 16 LL 53 55 65 68 70 73 MB M16*1.5 M16*1.5 M22*1.5 M22*1.5 M24*2 M30*2 MM(Ф) 6 6 8 10 12 14 P 43.2 45 50 53 55 58 RH 6 6 7 7 8 9 EE M5 M5 G1/8 G1/8 G1/8 G1/8 VF 16 17.5 16 18 20 22 WF 22 23.5 24 25 30 32 XC 84 87.5 100 105 114 121 ZC 91 94.5 110 115 126 133 2. With switch (K type)

4. Back axis(T)

5. Rod side flange(F1)

6. Head rod side flange(F2)

7. Front foot rest(G1)

8. Foot rest(G)

9. Front movable trunnion(B1)

10. Back movable trunnion(B2)

11. Support(Z)

11. Front movable trunnion & support(B1X)

12. Back movable trunnion & support(B2Z)

Bore(Ф) 12 16 20 25 32 40 AE 33 33 42 42 50 58 AH 20 20 25 25 32 36 AL 14 14 16 16 25 25 AT1 3 3.2 4 4 4 4 AT2 8 3.2 3.2 3.2 4 4 AV 11 11 13 13 21 21 BD 8 8 10 10 12 14 BF 24 24 32 32 36 40 BH 25 25 32 32 36 40 BG(Ф) 5.5 5.5 6.6 6.6 6.6 6.6 BT 3.2 3.2 3.2 3.2 4 4 BU 36 36 48 48 52 56 EF 26 26 38 38 47 51 KA 102 102 124 129 140 149 LB 14 14 16 16 25 25 ML 13 13 18 18 22 24 NL 12 12 17 17 20 21 PA 25 25 30 30 31 35 R 32 32 40 40 45 50 SA 81 83 97 100 120 123 SK 31 33 39 42 28 31 Bore(Ф) 12 16 20 25 32 40 TB 77 82.5 92 98 106 112 TD(Ф) 68 68 88 88 108 128 TF 40 40 50 50 58 70 TL 6 6 8 8 10 12 TM 28 28 36 36 44 50 TU 24 24 32 32 36 44 UA 44 44 55 55 60 65 UF 52 52 65 65 72 84 UM 40 40 52 52 64 74 WL 33 34.5 37 38 51 53 WM1 71 71 87 87 95 101 WM2 55 55 67 67 67 71 XG 18 19.5 19 20 24 23 XM1 59 59 71 71 79 85 XM2 43 43 51 51 51 55 XJ 73 75 91 95 102 108 XT 97 100 117 122 132 138 ZA 95 98.5 112 116 133 138 ZF 78 81.5 92 97 104 109 ZJ 75 78.5 88.5 93.5 101 106 ZX 69 71 85 90 96 101

Product Message

Other Products