Main Products

CONTACT US

Address: No.5 Shunhai Road, Yangting Town, Weihai City, Shandong Province

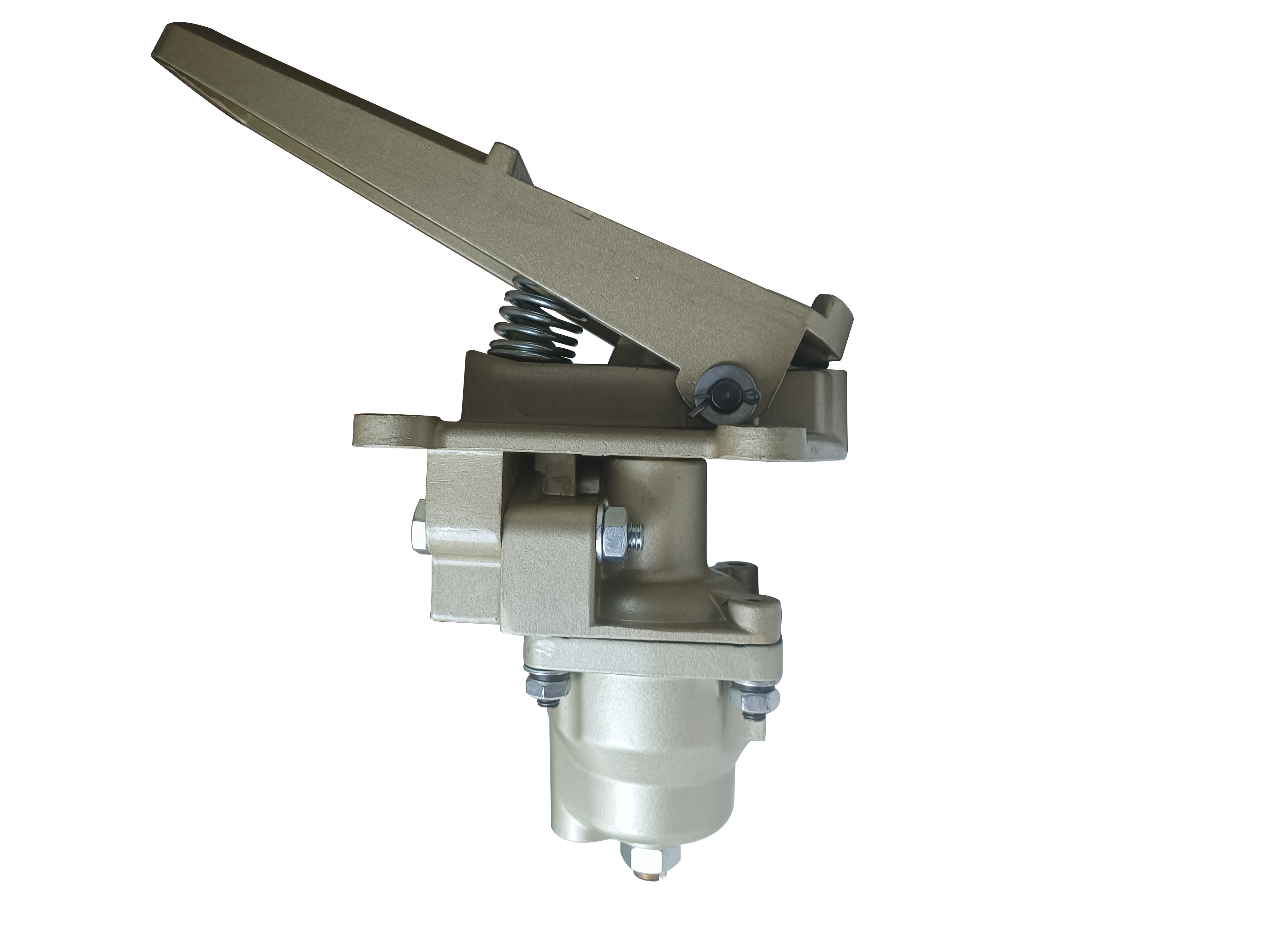

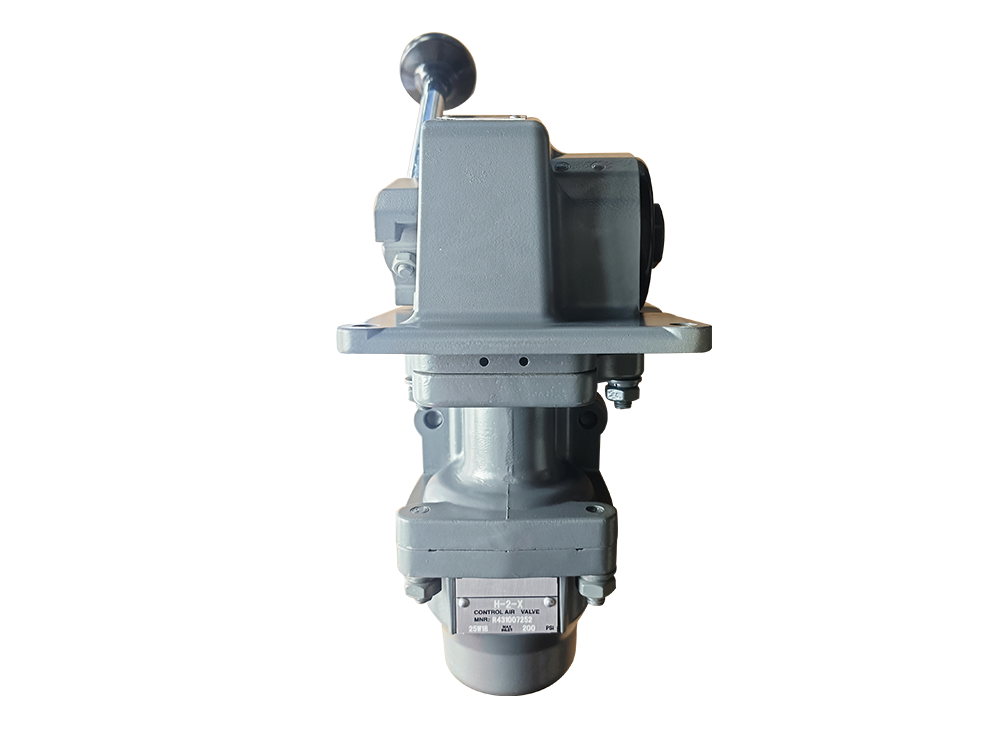

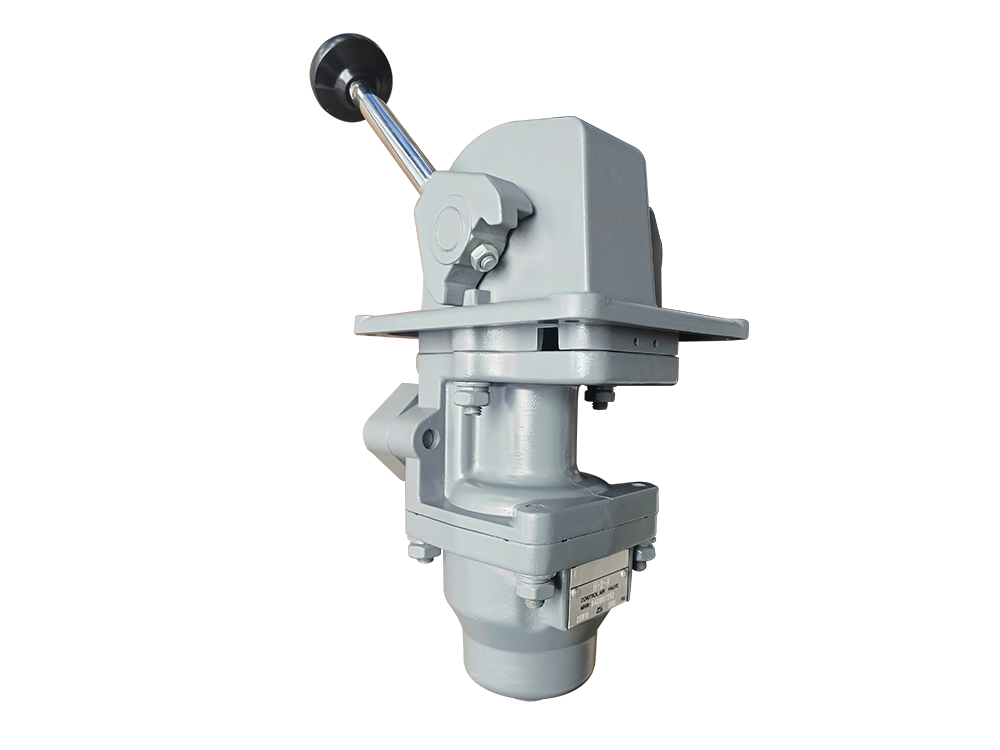

QGBQ Light Cylinder

零售价

市场价

Keywords:

QGBQ

Category:

Tel:

E-mail:

重量

库存

隐藏域元素占位

- Detail

- Dimension in Inches

-

- Commodity name: QGBQ Light Cylinder

- Commodity ID: 237

QGBQ series cylinders have standard type ,with valve type,with switch and valve cylinder. all of them are single piston rod and double acting,both ends cushion and not required lubrication.three type cylinders are come from QGBQ. The cylinders appearance and mounting dimension suit to ISO6430 intermational atandard.

1. Parameter

Type QGBQ(Basic) QGBQ-F(Valve set) QGBQ-K(switch set) QGBQ-FK (SV set) Bore in mm (Ømm) 32 40 50 63 80 100 32 40 50 63 80 100 Max. Stroke (mm) 500 800 1000 500 800 1000 Working Pressure 0.05--0.8MPa 0.15--0.8MPa Pressure-proof 1.2MPa Working Speed 50--70mm/sec 50--500mm/sec Working temperature 5--60ºC 5--50ºC Medium Air or dry air Lubrication Unnecessary but possible Cushion Cushion at both end Tolerance of Stroke in mm S<=500mm Ø32; Ø40; Ø50:0+2.0 Ø63; Ø80; Ø100:0+2.5 S>=501mm Ø32; Ø40; Ø50:0+2.5 Ø63; Ø80; Ø100:0+3.0 Cushioning Stoke (mm) 20 25 20 25 Theoretical transmitting force(N)(at pressure of 0.5MPa) Push 392 608 960 1519 2460 3842 392 608 960 1519 2460 3842 Pull 333 510 774 1333 2215 3606 333 510 774 1333 2215 3606 a. Technical Data for Switch

Type CK-J1A.CK-J1B Operating Voltage AC.DC: 24--220V Operating Current 10--300mA Max. Contact Capacity 16W Current Leakage 0 Voltage-proof 1500V Lamp Brighten at ON Acting time <=1msec Insulation resistance >=1.5MΩ Available Cylinder CK-J1: QGBQ32-50 CK-J1B: QGBQ63-100 Operating temprature -10--+70ºC Ambinent relative humidity <=90% Available Unit Program Controller, Relay etc. b. Technical Data for Valve

c. Min. stroke for cylinder

Cylinder Mounting Except MT4 For MT4 mounting Switch With Soft wire With Soft wire Cylinder with switch (QGBQ-K) 20mm 125mm Cylinder with valve (QGBQ-F) 60mm 75mm 2. Cylinder type explaination

For example

The air cylinder have valve, switches,bore Ø50mm,stroke 80mm double clevis type, two DC switches, anamnestic valve,voltage DC12V, DIN link wires. Then: QGBQ-50-80MF1-FC6D-KE2

3. Symbol

4. Models

1. QGBQ-K is with switches cylinders,cylinders stroke can be adjusted easy.

2. QGBQ-F with valve cylinders save connecting time and space because of combined cylinder and valve.so install and repair quickly. There are 2 kinds: single control and double control.

Cylinders with single control have Pushing when electrify valve and plling when electrify valve.because valves can interchange so the cylinder action could interchange too.single control valve has no-memory,when turn of electricity,the valve rod return position,the cylinder change direction also.

The cylinders with Double control valve are self-holding,the valve can memory ,when turn off electricity ,the valve rod dont moving and the cylinder rod hold,so turn off electricity suddenly dont affect the cylinder.

The cylinders with valve install small and low-power solenoid first valve,winding all coverd by plastic,sealed and safety.

3. QGBQ-FK cylinders are combined by cylinder with valve and switch,that are small automation system , achieve machine and electricity intrgrative.

4. Double piston rods and backward stroke adjustable and forward stroke adjustable cylinder are coming from QGBQ, almost all accessory are same.double piston rods cylinder can output force both ends. backward stroke adjustable and forward stroke adjustable cylinder are mounted limit.so the cylinder could adjust stroke.

-

1. Overall dimension 1

*In other mounting style reference over table,common manufacture size"B"is not working surface,if need working surface can ask please.

1. Intermediate fixed or movable trunnion type(MT4)

2. Single clevis type(MP3)

3. Single clevis type(P3)

4. Double clevis type(MP1)

5. Vertical to axis foot type(MS2)

7. Parallet to axis foot type(S2)

8. Rod side flange type(MF1)

9. Head side flange type(MF2)

Bore(Ф) 32 40 50 63 80 100 F 10 10 10 12 16 16 FB(Ф) 7 7 9 9 12 12 R 33 36 47 56 70 84 TF 58 70 86 98 119 138 UF 72 84 104 116 143 162 ZF 128 128 128 133 159 159 E 44 51 62 75 94 112 LH 22 26 31 38 47 57 SS 73 73 73 76 82 82 ST 8 8 9 9 14 14 SU 13 14 14 14 18 18 SY 22 22 24 26 33 37 TS 63 70 83 95 121 140 US 80 91 104 116 146 165 XS 35 35 35 35 48 48 XW 108 108 108 111 130 130 ZS 130 130 132 137 163 167 AB(Ф) 9 12 12 12 14 14 AE 50 55.5 67.5 79 96 113 AH 28 30 36.5 42 51 59 AL 20.5 23.5 28 31 30 30 Bore(Ф) 32 40 50 63 80 100 AO 9.5 12.5 12 13 16 16 AT 3.2 3.2 4 4 6 6 SA 134 140 14 158 168 168 UA 50 57 68 80 97 112 XA 138.5 141.5 146 152 173 173 ZA 148 154 158 165 189 189 SB(Ф) 9 12 12 12 14 14 CD(Ф) 12H9/f8 14H9/f8 14H9/f8 14H9/f8 20H9/f8 20H9/f8 CP 46 58 66 66 78 78 UB 32 44 52 52 64 64 BD 30 30 30 30 35 40 TD(Ф) 16H9/e9 25H9/e9 25H9/e9 25H9/e9 25H9/e9 25H9/e9 TL 16 25 25 25 25 25 TM 55 63 76 88 114 132 TR R1.5 R1.5 R1.5 R1.5 R1.6 R2 UM 52 59 71 84 104 128 UW 52 59 71 84 104 128 XI 71.5 71.5 71.5 73 89 89 Bore(Ф) 32 40 50 63 80 100 EW MP1 16 20 20 20 32 32 MP3 16 20 20 20 32 32 P3 16 20 20 20 32 32 MR MP1 R15 R15 R17 R17 R23 R23 MP3 R14 R16 R16 R16 R22 R22 P3 R12 R14 R15 R15 R20 R20 T MP1 8 8 8 8 11 11 MP3 8 8 10 13 18 18 P3 8 10 10 10 14 14 LR MP1 R18 R18 R19 R19 R32 R32 MP3 R17 R17 R19 R19 R32 R32 P3 R16 R16 R18 R18 R25 R25 XC MP1 137 137 137 140 175 175 MP3 P3 147 152 152 155 196 196 ZC MP1 150 150 152 155 196 196 MP3 149 151 151 154 195 195 P3 159 166 167 170 211 211 EF 47 52 65 76 94 115 W 15 15 15 13 19 19

QGBQ Light Cylinder

QGBQ series cylinders have standard type ,with valve type,with switch and valve cylinder. all of them are single piston rod and double acting,both ends cushion and not required lubrication.three type cylinders are come from QGBQ. The cylinders appearance and mounting dimension suit to ISO6430 intermational atandard.

keyword:

Category:

Pneumatic Cylinder

Tel:

E-mail:

- Detail

- Dimension in Inches

-

- Commodity name: QGBQ Light Cylinder

- Commodity ID: 237

QGBQ series cylinders have standard type ,with valve type,with switch and valve cylinder. all of them are single piston rod and double acting,both ends cushion and not required lubrication.three type cylinders are come from QGBQ. The cylinders appearance and mounting dimension suit to ISO6430 intermational atandard.

1. Parameter

Type QGBQ(Basic) QGBQ-F(Valve set) QGBQ-K(switch set) QGBQ-FK (SV set) Bore in mm (Ømm) 32 40 50 63 80 100 32 40 50 63 80 100 Max. Stroke (mm) 500 800 1000 500 800 1000 Working Pressure 0.05--0.8MPa 0.15--0.8MPa Pressure-proof 1.2MPa Working Speed 50--70mm/sec 50--500mm/sec Working temperature 5--60ºC 5--50ºC Medium Air or dry air Lubrication Unnecessary but possible Cushion Cushion at both end Tolerance of Stroke in mm S<=500mm Ø32; Ø40; Ø50:0+2.0 Ø63; Ø80; Ø100:0+2.5 S>=501mm Ø32; Ø40; Ø50:0+2.5 Ø63; Ø80; Ø100:0+3.0 Cushioning Stoke (mm) 20 25 20 25 Theoretical transmitting force(N)(at pressure of 0.5MPa) Push 392 608 960 1519 2460 3842 392 608 960 1519 2460 3842 Pull 333 510 774 1333 2215 3606 333 510 774 1333 2215 3606 a. Technical Data for Switch

Type CK-J1A.CK-J1B Operating Voltage AC.DC: 24--220V Operating Current 10--300mA Max. Contact Capacity 16W Current Leakage 0 Voltage-proof 1500V Lamp Brighten at ON Acting time <=1msec Insulation resistance >=1.5MΩ Available Cylinder CK-J1: QGBQ32-50 CK-J1B: QGBQ63-100 Operating temprature -10--+70ºC Ambinent relative humidity <=90% Available Unit Program Controller, Relay etc. b. Technical Data for Valve

c. Min. stroke for cylinder

Cylinder Mounting Except MT4 For MT4 mounting Switch With Soft wire With Soft wire Cylinder with switch (QGBQ-K) 20mm 125mm Cylinder with valve (QGBQ-F) 60mm 75mm 2. Cylinder type explaination

For example

The air cylinder have valve, switches,bore Ø50mm,stroke 80mm double clevis type, two DC switches, anamnestic valve,voltage DC12V, DIN link wires. Then: QGBQ-50-80MF1-FC6D-KE2

3. Symbol

4. Models

1. QGBQ-K is with switches cylinders,cylinders stroke can be adjusted easy.

2. QGBQ-F with valve cylinders save connecting time and space because of combined cylinder and valve.so install and repair quickly. There are 2 kinds: single control and double control.

Cylinders with single control have Pushing when electrify valve and plling when electrify valve.because valves can interchange so the cylinder action could interchange too.single control valve has no-memory,when turn of electricity,the valve rod return position,the cylinder change direction also.

The cylinders with Double control valve are self-holding,the valve can memory ,when turn off electricity ,the valve rod dont moving and the cylinder rod hold,so turn off electricity suddenly dont affect the cylinder.

The cylinders with valve install small and low-power solenoid first valve,winding all coverd by plastic,sealed and safety.

3. QGBQ-FK cylinders are combined by cylinder with valve and switch,that are small automation system , achieve machine and electricity intrgrative.

4. Double piston rods and backward stroke adjustable and forward stroke adjustable cylinder are coming from QGBQ, almost all accessory are same.double piston rods cylinder can output force both ends. backward stroke adjustable and forward stroke adjustable cylinder are mounted limit.so the cylinder could adjust stroke.

-

1. Overall dimension 1

*In other mounting style reference over table,common manufacture size"B"is not working surface,if need working surface can ask please.

1. Intermediate fixed or movable trunnion type(MT4)

2. Single clevis type(MP3)

3. Single clevis type(P3)

4. Double clevis type(MP1)

5. Vertical to axis foot type(MS2)

7. Parallet to axis foot type(S2)

8. Rod side flange type(MF1)

9. Head side flange type(MF2)

Bore(Ф) 32 40 50 63 80 100 F 10 10 10 12 16 16 FB(Ф) 7 7 9 9 12 12 R 33 36 47 56 70 84 TF 58 70 86 98 119 138 UF 72 84 104 116 143 162 ZF 128 128 128 133 159 159 E 44 51 62 75 94 112 LH 22 26 31 38 47 57 SS 73 73 73 76 82 82 ST 8 8 9 9 14 14 SU 13 14 14 14 18 18 SY 22 22 24 26 33 37 TS 63 70 83 95 121 140 US 80 91 104 116 146 165 XS 35 35 35 35 48 48 XW 108 108 108 111 130 130 ZS 130 130 132 137 163 167 AB(Ф) 9 12 12 12 14 14 AE 50 55.5 67.5 79 96 113 AH 28 30 36.5 42 51 59 AL 20.5 23.5 28 31 30 30 Bore(Ф) 32 40 50 63 80 100 AO 9.5 12.5 12 13 16 16 AT 3.2 3.2 4 4 6 6 SA 134 140 14 158 168 168 UA 50 57 68 80 97 112 XA 138.5 141.5 146 152 173 173 ZA 148 154 158 165 189 189 SB(Ф) 9 12 12 12 14 14 CD(Ф) 12H9/f8 14H9/f8 14H9/f8 14H9/f8 20H9/f8 20H9/f8 CP 46 58 66 66 78 78 UB 32 44 52 52 64 64 BD 30 30 30 30 35 40 TD(Ф) 16H9/e9 25H9/e9 25H9/e9 25H9/e9 25H9/e9 25H9/e9 TL 16 25 25 25 25 25 TM 55 63 76 88 114 132 TR R1.5 R1.5 R1.5 R1.5 R1.6 R2 UM 52 59 71 84 104 128 UW 52 59 71 84 104 128 XI 71.5 71.5 71.5 73 89 89 Bore(Ф) 32 40 50 63 80 100 EW MP1 16 20 20 20 32 32 MP3 16 20 20 20 32 32 P3 16 20 20 20 32 32 MR MP1 R15 R15 R17 R17 R23 R23 MP3 R14 R16 R16 R16 R22 R22 P3 R12 R14 R15 R15 R20 R20 T MP1 8 8 8 8 11 11 MP3 8 8 10 13 18 18 P3 8 10 10 10 14 14 LR MP1 R18 R18 R19 R19 R32 R32 MP3 R17 R17 R19 R19 R32 R32 P3 R16 R16 R18 R18 R25 R25 XC MP1 137 137 137 140 175 175 MP3 P3 147 152 152 155 196 196 ZC MP1 150 150 152 155 196 196 MP3 149 151 151 154 195 195 P3 159 166 167 170 211 211 EF 47 52 65 76 94 115 W 15 15 15 13 19 19

Product Message

Other Products